The language of the surface

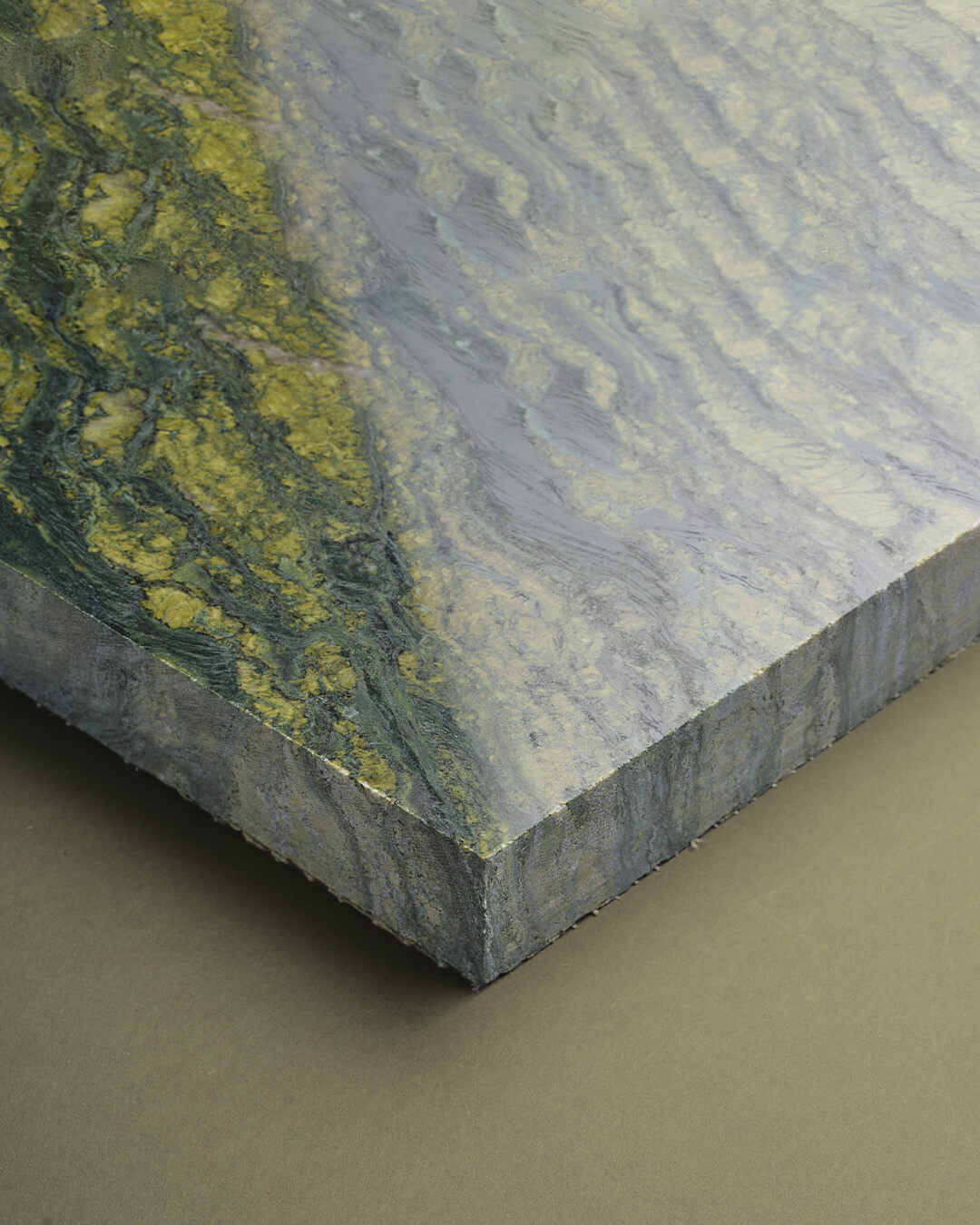

Traditional finishes are the basic surface treatments applied to natural stone to define its texture, appearance and surface behaviour. Through industrial processes acting on the surface, they modify visual perception, tactile feel and the way the material performs within the project.

Many of these finishes can be adjusted in intensity, producing more or less pronounced results according to aesthetic and technical needs. Each stone type reacts differently: mineral composition, veining and structure create unique outcomes, especially with more textured finishes such as satin finish, flaming, sandblasting and brushing.

Credits: Luca Morandini